Bacteria control without

using toxic chemicals

How

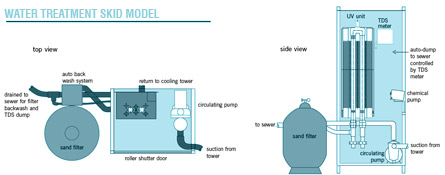

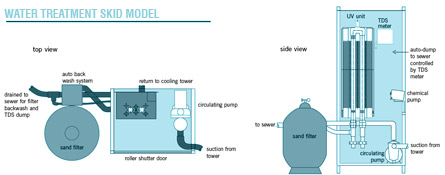

the system works

The cooling tower unit

contains it own circulating pump, which draws

water from the cooling tower basin and passes

it through a sand filter, then through the UV

unit and back into the cooling tower basin. Back

washing of the sand filter is done automatically

by a fully programmable digital timer using solenoid

valves, although it can be done manually if required.

The

advantages:

- It can run 24 hours

per day, 365 days per year while giving a consistently

high level of protection from infestations,

such as Legionella pneumophila, which causes

Legionaires disease.

- Quick and easy installation,

often without needing to shut down the cooling

tower.

Small

enclosed units

UVTA

model numbers CT LC30, CT LC80 and CT LC110. The

unit includes pump, UV unit, programmable digital

timer, automatic back wash sand filter, interconnecting

pipework and wiring, back wash water tank and

central inlet power point. All equipment except

the filter, are mounted inside an enclosure. Also

available are; TDS monitor control systems and

test kits.

Large

enclosed units

UVTA

model numbers CT52L, CT100L. The unit includes

a pump, UV unit, programmable digital timer, automatic

back wash sand filter, interconnecting pipe work

and wiring, TDS controller, chemical injection

pump, test kits, back wash water tank and a central

inlet power point all mounted inside a roller

door enclosure.

UVTA

- UV Systems

|

UV |

|

Chlorine |

|

Non corrosive Non corrosive

Proven effectiveness in Legionella control Proven effectiveness in Legionella control

Low cost to run Low cost to run

No storage required No storage required

Built-in interlocks for Built-in interlocks for

complete safety

|

Safety |

Corrosive Corrosive

Unstable in storage Unstable in storage

Care required in handling Care required in handling

Can be toxic and has been connected to carcinogens Can be toxic and has been connected to carcinogens

Changes pH in the water Changes pH in the water

|

| |

|

|

|

UV |

UVTA |

Biocides |

|  No toxic or harmful chemicals

needed No toxic or harmful chemicals

needed

Approved by NSW Health dept Approval No.PDA 001 Approved by NSW Health dept Approval No.PDA 001

|

Health

Hazards |

Inhalation of toxic chemical

drift Inhalation of toxic chemical

drift

|

|  No effect on pH or chemical

composition of the water No effect on pH or chemical

composition of the water

|

Effect

on Water |

Changes pH and water composition Changes pH and water composition

|

|  Low initial capital cost. Low initial capital cost.

Minimal operational/ maintenance costs. Minimal operational/ maintenance costs.

|

Cost |

Expensive to operate safely Expensive to operate safely

Can be corrosive on equipment and piping Can be corrosive on equipment and piping

|

Correctly sized UVTA

Ultraviolet Disinfection Systems can be easily

incorporated into the existing basin. Water volume

is calculated and UV unit sized in order to turn

over the entire volume of water every 10-60 minutes.

A circulating pump takes water from one side of

the basin, passing through a filter, then through

the UV unit, and the disinfected water is returned

to the opposite side of the basin.

Cooling

Tower Models

|

Maximum

Cooling Tower

Pond Capacity (Litres)

|

UVTA Model Number

|

| 200

- 1,000

1,000 - 2,500

2,500 - 4,000

6,000 - 12,000

12,000 - 22,000 |

LC30

LC80

LC110

52L

100L

|

|